S h e e t M e t a l F a b r i c a t i o n

Sheet Metal Shearing

Quick, efficient precision sheet metal shearing with clean, burr-free cuts for seamless integration into downstream processes.

S h e e t M e t a l F a b r i c a t i o n

Sheet Metal Shearing

Fast and precise sheet metal shearing with FTI Manufacturing- a cost-efficient, low-waste solution for cutting sheets or blanks to custom dimensions.

Quick • Efficient • Low-Waste

Rapid, Precise Sheet Metal Shearing

At FTI Manufacturing, shearing is a foundational step in our precision sheet metal fabrication workflow, ensuring dimensionally accurate blanks and minimal material waste. Sheet metal is available in various dimensions, typically ranging from 36″–60″ in width and 96″–144″ in length, and must be cut into smaller blanks tailored to the size requirements of the final components.

Our shearing process begins by securely clamping a sheet of metal between the top and bottom blades of our advanced shearing machines. As the top blade slices through, the material is pressed onto the lower blade, cleanly removing excess metal to produce smooth, accurate blanks. Utilizing a synchronized moving beam, electronically adjustable rake angle, and precise blade gap control, the process ensures twist-free, consistent results. Hydraulic clamping and programmable stroke lengths further optimize cutting for both large-format sheets and smaller pieces, delivering high-quality, functional components ready for downstream fabrication.

Our skilled shearing team, supported by digital controls and DRO-enabled back gauges, produces precise blanks ready for turret punching, bending, and assembly. With low-maintenance hydraulics, hardened guideways, and high-alloy four-side usable blades, FTI Manufacturing’s shearing system guarantees premium cut quality, durability, and productivity, ensuring your parts meet exact standards with zero compromise.

Sheet Metal Shearing Features

Shearing Machinery Capabilities

At FTI Manufacturing, our shearing machinery is engineered for precision, efficiency, and consistent results:

- Machinery: JEKSON CNC Hydraulic Shearing Machine

- Sheet metal dimensions: Up to 60″ wide and 120″–144″ long

- Sheet metal thickness: Up to 6 mm

- Tensile strength: Up to 45 kg/sq mm

- Stroke speed: Optimized for both large-format and short-piece cutting

This setup ensures twist-free, burr-free cuts and exceptional repeatability, supporting both short-run precision jobs and high-volume production with ease.

Benefits of FTI’s Shearing Service

FTI Manufacturing offers a precise and efficient sheet metal shearing solution designed to meet diverse customer needs:

- Minimal Waste: Clean cuts with no chips, reducing material loss.

- In-House Processing: All shearing is performed on-site, maintaining full quality control.

- Cost-Effective: Optimized processes lower production costs without compromising accuracy.

- Expert Handling: Skilled operators evaluate and manage every sheet to ensure consistent, high-quality results.

Engineering & Design Support

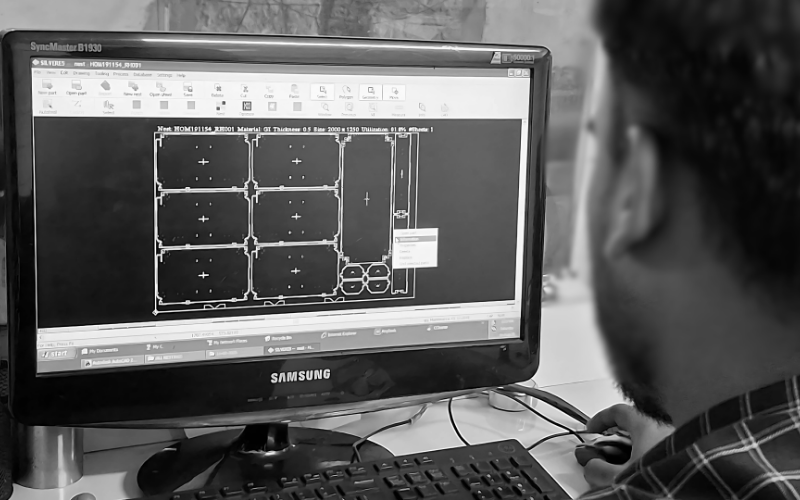

At FTI Manufacturing, our in-house engineering and design team provides end-to-end support from concept to production. Whether it’s new product development, design optimization, or reverse engineering, we work collaboratively with our clients to develop cost-effective, manufacturable solutions tailored to their specific needs.

Our team is proficient in handling a wide range of industry demands and production challenges. We assist in refining part geometries, simplifying fabrication processes, and reducing material and operational costs, helping our clients improve functionality without compromising efficiency or quality.

FTI supports direct import and unfolding of 3D models in formats such as .dwg, .step, .iges, .sldasm, .sldprt, and .dxf using tools like SolidWorks, AutoCAD, and other major CAD platforms. These files are seamlessly integrated into our CAM workflow, enabling faster processing, reduced errors, and shortened lead times for your sheet metal components

Lean, JIT & Kanban – Driving Efficiency from Concept to Delivery

At FTI Manufacturing, we leverage the Just-In-Time (JIT) inventory strategy to align production precisely with your ordering needs. This reduces idle inventory, optimizes costs, and ensures you receive a high-quality product delivered on time, every time, at a competitive price.

We pair JIT with the Kanban system to streamline our lean production practices. By setting clear minimum and maximum stock levels, we maintain a highly responsive pull-based system that adapts to your demand without unnecessary waste.

Our approach not only reduces excess inventory for both customers and suppliers but also ensures seamless production flow and faster lead times. With full pipeline visibility through our tracking systems, FTI keeps your supply chain running smoothly, reliably, and efficiently.

Is FTI Manufacturing's Sheet Metal Shearing Service Right for Your Next Project?

With deep experience across diverse fabrication projects—ranging from straightforward components to intricate, large-scale assemblies, FTI Manufacturing delivers precision-cut blanks and sheets tailored to your specifications, using a CNC shearing process that ensures clean, burr-free cuts with high repeatability.

Our JEKSON CNC shearing machine, with a cutting capacity of up to 6 mm thickness and 10 feet length, is equipped with advanced features like a DRO-enabled back gauge, electronically adjustable rake angle, and synchronized hydraulic beam movement, enabling us to deliver fast and accurate shearing across various materials.

Our Promise

Sheet Metal Shearing Guarantee

FTI Manufacturing is more than just a sheet metal fabricator, we are a manufacturing partner invested in your success. With over 35+ years of experience, we have built lasting client relationships by delivering not only high-quality parts but also the reliability, consistency, and trust businesses count on.

Comprehensive Capabilities Under One Roof

With a wide range of precision sheet metal fabrication services, including rapid prototyping, CNC machining, sheet metal forming, fabrication, and finishing, FTI Manufacturing provides complete solutions without the need for multiple vendors. This integrated approach ensures better quality control, faster turnaround times, and cost efficiency.

Invested in Your Process, Committed to Your Success

At FTI Manufacturing, we understand that choosing a manufacturing partner is about more than just capabilities, it’s about trust, collaboration, and results. We work closely with our customers at every stage, offering engineering expertise, process optimization, and reliable delivery that helps your projects succeed.

One Team

Your Single-Source Sheet Metal Manufacturing Partner

At FTI Manufacturing, we simplify your journey by being your one-stop partner. One vendor, one purchase order, and one accountable team driving your project to success.

One Destination

End-to-end Services, Unmatched Capabilities

FTI brings the full spectrum of precision sheet metal fabrication services under one roof. From rapid prototyping to full-scale production, our integrated process ensures faster lead times, seamless coordination, and exceptional quality.

One Vision

Redefining the Standard in Sheet Metal Fabrication

For decades, FTI Manufacturing has been shaping the future of precision sheet metal manufacturing. Our reputation is built on trust, innovation, and craftsmanship, backed by a team of engineers and experts dedicated to excellence. We don’t just deliver parts; we deliver confidence, consistency, and a vision of long-term partnership.

FTI Manufacturing Delivers Excellence

At FTI Manufacturing, we recognize that our clients create innovative products designed to endure extreme conditions, and serve highly specialized purposes. We take pride in getting it right the first time and delivering on schedule. We value our vital role in the success of your project and commit to doing our part to help you reach the finish line without delays.