S h e e t M e t a l F a b r i c a t i o n

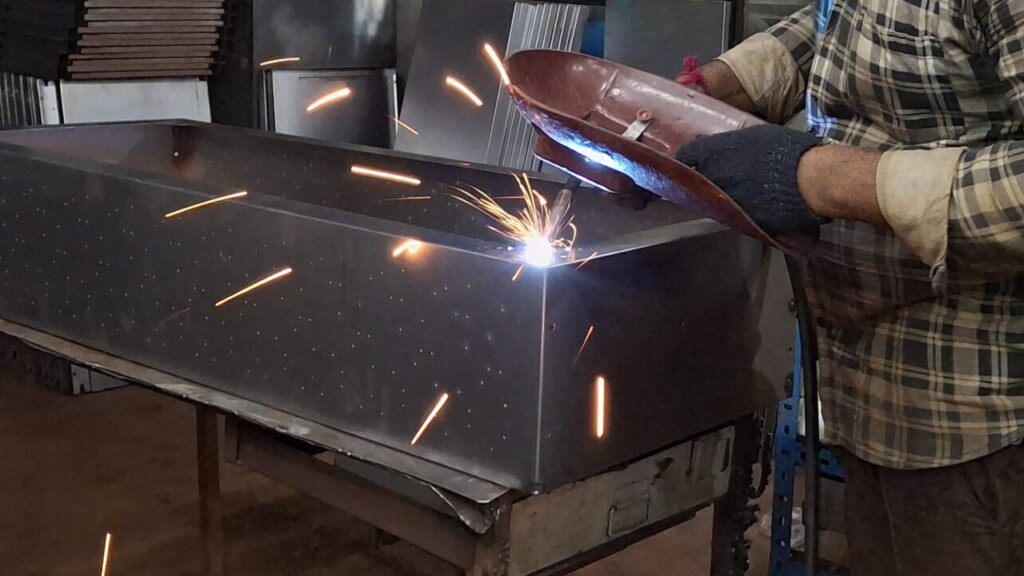

Sheet Metal Welding

High-quality, cost-effective sheet metal welding performed on-site by FTI Manufacturing’s skilled welding experts.

High-Quality • Superior Craftsmanship

Expert, In-House Sheet Metal Welding

At FTI Manufacturing, we understand that precise and reliable welding is critical to producing high-quality sheet metal parts. Our welding department is equipped with a versatile fleet of machines, including 7 CO₂ (MIG) welding stations, 2 Arc welding setups, and 3 stationary spot welding machines, allowing us to handle both intricate precision jobs and heavy-duty structural assemblies efficiently in-house.

Our CO₂ (MIG) welding system uses a continuously-fed wire electrode with shielding gas to protect the weld area, offering high deposition rates, minimal spatter, and strong weld integrity, perfect for fabricating frames, brackets, enclosures, and load-bearing components.

For structural reinforcements and thicker materials, our Arc welding (MMAW) stations provide deep penetration and robust joins, making it ideal for repairs and heavy-duty assemblies.

With a skilled team of certified welders and in-house quality control, FTI Manufacturing ensures every weld meets your exact specifications for strength, accuracy, and finish. Whether you’re producing prototypes or high-volume runs, our in-house welding capabilities reduce lead times, control costs, and maintain consistent quality across all projects.

Sheet Metal Welding Features

FTI Manufacturing’s Sheet Metal Welding Techniques

welding techniques, ensuring high-quality results for every project:

CO₂ (MIG) Welding – Metal Inert Gas welding uses a continuously-fed wire electrode along with shielding gas to protect the weld area from contamination. Ideal for structural components and heavy-duty applications, MIG welding provides high deposition rates, strong welds, and cost-effectiveOur experienced welding team at FTI is equipped to deliver a wide range of skilled production.

Arc (MMAW) Welding – Manual Metal Arc welding uses a flux-coated consumable electrode to create deep, reliable welds. This technique is perfect for thick materials and structural reinforcements, offering robust joins and consistent quality.

Spot Welding – Resistance spot welding joins flat metal surfaces using heat and pressure applied through copper electrodes. Efficient and cost-effective, spot welding minimizes distortion and eliminates the need for fasteners, making it a staple in precision sheet metal fabrication.

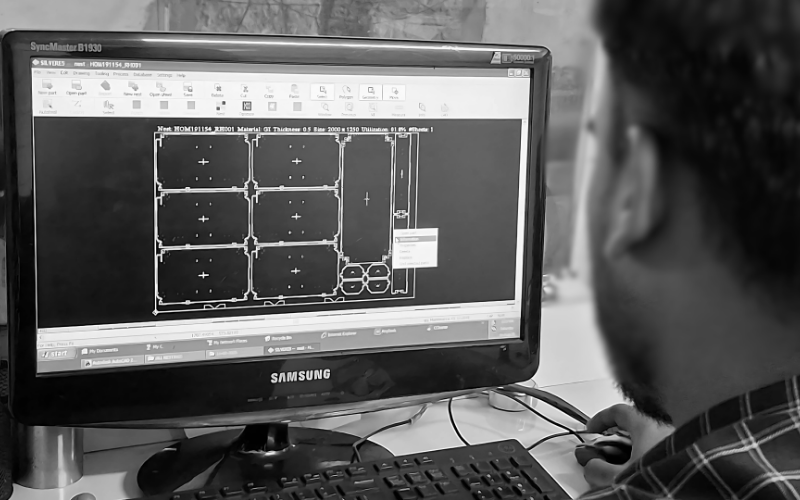

Collaborative Design & Manufacturing Excellence

At FTI Manufacturing, our in-house engineering and design team provides end-to-end support from concept to production. Whether it’s new product development, design optimization, or reverse engineering, we work collaboratively with our clients to develop cost-effective, manufacturable solutions tailored to their specific needs.

Our team is proficient in handling a wide range of industry demands and production challenges. We assist in refining part geometries, simplifying fabrication processes, and reducing material and operational costs, helping our clients improve functionality without compromising efficiency or quality.

FTI Manufacturing supports direct import and unfolding of 3D models in formats such as .dwg, .step, .iges, .sldasm, .sldprt, and .dxf using tools like SolidWorks, AutoCAD, and other major CAD platforms. These files are seamlessly integrated into our CAM workflow, enabling faster processing, reduced errors, and shortened lead times for your sheet metal components

Lean, JIT & Kanban – Driving Efficiency from Concept to Delivery

At FTI Manufacturing, we leverage the Just-In-Time (JIT) inventory strategy to align production precisely with your ordering needs. This reduces idle inventory, optimizes costs, and ensures you receive a high-quality product delivered on time, every time, at a competitive price.

We pair JIT with the Kanban system to streamline our lean production practices. By setting clear minimum and maximum stock levels, we maintain a highly responsive pull-based system that adapts to your demand without unnecessary waste.

Our approach not only reduces excess inventory for both customers and suppliers but also ensures seamless production flow and faster lead times. With full pipeline visibility through our tracking systems, FTI Manufacturing keeps your supply chain running smoothly, reliably, and efficiently.

Sheet Metal Welding Features

Are FTI Manufacturing’s Metal Spot welding Services Right for Your Next Project?

Our team made up of skilled craftspeople, and highly qualified Welders, is able to complete a variety of complex and specified processes to meet the exact needs of your project.

FTI Manufacturing’s extensive industry experience and attention to detail allow us to advise customers on their project’s welding needs confidently

Our Promise

Spot Welding Guarantee

FTI Manufacturing is more than just a sheet metal fabricator, we are a manufacturing partner invested in your success. With over 35+ years of experience, we have built lasting client relationships by delivering not only high-quality parts but also the reliability, consistency, and trust businesses count on.

Comprehensive Capabilities Under One Roof

With a wide range of precision sheet metal fabrication services, including rapid prototyping, CNC machining, sheet metal forming, fabrication, and finishing, FTI Manufacturing provides complete solutions without the need for multiple vendors. This integrated approach ensures better quality control, faster turnaround times, and cost efficiency.

Invested in Your Process, Committed to Your Success

At FTI Manufacturing, we understand that choosing a manufacturing partner is about more than just capabilities, it’s about trust, collaboration, and results. We work closely with our customers at every stage, offering engineering expertise, process optimization, and reliable delivery that helps your projects succeed.

One Team

Your Single-Source Sheet Metal Manufacturing Partner

At FTI Manufacturing, we simplify your journey by being your one-stop partner. One vendor, one purchase order, and one accountable team driving your project to success.

One Destination

End-to-end Services, Unmatched Capabilities

FTI Manufacturing brings the full spectrum of precision sheet metal fabrication services under one roof. From rapid prototyping to full-scale production, our integrated process ensures faster lead times, seamless coordination, and exceptional quality.

One Vision

Redefining the Standard in Sheet Metal Fabrication

For decades, FTI Manufacturing has been shaping the future of precision sheet metal manufacturing. Our reputation is built on trust, innovation, and craftsmanship, backed by a team of engineers and experts dedicated to excellence. We don’t just deliver parts; we deliver confidence, consistency, and a vision of long-term partnership.

FTI Manufacturing Delivers Excellence

At FTI Manufacturing, we recognize that our clients create innovative products designed to endure extreme conditions, and serve highly specialized purposes. We take pride in getting it right the first time and delivering on schedule. We value our vital role in the success of your project and commit to doing our part to help you reach the finish line without delays.