S h e e t M e t a l F a b r i c a t i o n

Packaging

Secure packing, engineered to safeguard every component from factory to field.

Precise • Fast

Packaging for Safe Handling & Transport

At FTI Manufacturing, we recognize that a project isn’t complete until it is packed, protected, and ready to reach you in perfect condition. That’s why our professional packing line is designed to handle every product with care and precision. Each item is carefully placed into boxes as per customer requirements, ensuring the right fit and maximum safety during transportation. Our process includes secure strapping, accurate weighing, and detailed labeling, guaranteeing that products are delivered damage-free and ready for use.

With an organized and standardized packing system, FTI Manufacturing ensures consistency, efficiency, and reliability across all shipments. Whether it’s a single unit or a bulk order, our packing services add value by safeguarding your products and streamlining logistics, so you can trust that every order leaves our facility protected and professional.

Sheet Metal Packing Features

Packing

Every product manufactured at FTI is packaged with precision and care. Our custom packaging solutions are designed to protect components during handling and transit, ensuring they arrive at their destination damage-free and ready for use. From engineered crates to protective wraps and cushioning, we select packaging materials based on product geometry, finish, and transport conditions—delivering safety, quality, and customer satisfaction at every stage of delivery.

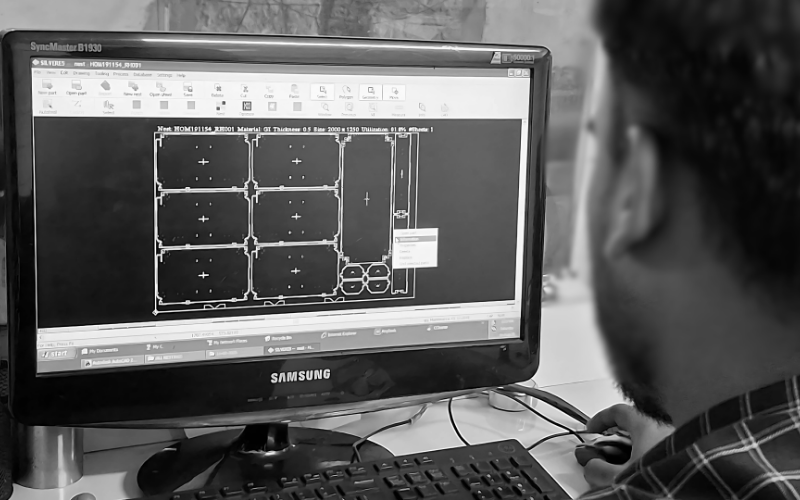

Collaborative Design & Manufacturing Excellence

At FTI, we believe that precision manufacturing begins with strong engineering collaboration. Our experienced design and engineering teams work closely with customers to transform ideas into manufacturable, cost-effective sheet metal products. With a robust foundation in Design for Manufacturability (DFM), Design for Assembly (DFA), Lean Principles, and Reverse Engineering, we help refine and enhance product designs to simplify production and reduce cost without compromising quality.

Our engineering capability is supported by the use of industry-leading software such as SolidWorks, AutoCAD, and 3DX, allowing us to work with a variety of file formats including .dwg, .step, .iges, .sldasm, .sldprt, and .dxf.

We specialize in industrial, office, and lab furniture, and bring deep process knowledge and material expertise to every project. With a cross-functional team comprising designers, product engineers, planners, quality controllers, supervisors, and dedicated project support, FTI ensures end-to-end engineering assistance—from concept to prototype to full-scale production.

We offer full support in:

- Design consultation and joint engineering reviews

- Prototyping, trials, and pilot runs

- Material and process optimization

- Production process planning backed by robust QA/QC systems

Whether you’re looking to optimize an existing design or develop a new product from the ground up, FTI is your reliable partner for precision sheet metal manufacturing.

Lean, JIT & Kanban – Driving Efficiency from Concept to Delivery

At FTI, our production philosophy is rooted in Lean manufacturing principles, ensuring that every step in the process creates value for the customer while eliminating waste – whether in time, resources, or motion. We focus on streamlining workflows, optimizing layouts, standardizing processes, and fostering continuous improvement to achieve the perfect balance between quality, speed, and cost.

Building on Lean, we apply the Just-In-Time (JIT) strategy to synchronize production with actual demand. This means we produce and deliver only what is needed, when it is needed, and in the exact quantity required – reducing overproduction, minimizing inventory holding costs, and freeing up working capital.

We combine JIT with the Kanban methodology to enable a seamless, demand-driven workflow. By setting precise minimum and maximum inventory levels, we operate on a pull-based system that reacts swiftly to changing customer needs. This lean manufacturing approach not only minimizes waste for clients and suppliers but also drives efficiency at every stage – from raw material sourcing to final dispatch – ensuring speed, quality, and value in every delivery.

Punching Expertise

As part of FTI’s integrated manufacturing capabilities, our CNC punching operations are built on a foundation of precision, speed, and reliability:

- State-of-the-art FINN-POWER CNC Turret Punching Machine

- Dedicated Quality Control Team and In-process Inspection Systems

- Collaborative Engineering Support for Design Optimization

- Decades of Experience in Precision Sheet Metal Processing

- Skilled Multidisciplinary Teams Across Projects, Production, QA, and Product Functions

- Ability to Handle Complex Geometries, Tight Tolerances, and Custom Features with Consistency

With a process-driven approach and deep understanding of material behavior and application needs, FTI delivers high-accuracy punched components that meet the demands of industrial furniture and specialized sheet metal assemblies – on time, every time.

Our Promise

Sheet Metal Packing Guarantee

FTI Manufacturing is more than just a sheet metal fabricator; we are a manufacturing partner invested in your success. With over 35+ years of experience, we have built lasting client relationships by delivering not only high-quality parts but also the reliability, consistency, and trust businesses count on.

Comprehensive Capabilities Under One Roof

With a wide range of precision sheet metal fabrication services, including rapid prototyping, CNC machining, sheet metal forming, fabrication, and finishing, FTI Manufacturing provides complete solutions without the need for multiple vendors. This integrated approach ensures better quality control, faster turnaround times, and cost efficiency.

Invested in Your Process, Committed to Your Success

At FTI Manufacturing, we understand that choosing a manufacturing partner is about more than just capabilities; it’s about trust, collaboration, and results. We work closely with our customers at every stage, offering engineering expertise, process optimization, and reliable delivery that helps your projects succeed.

One Team

Your Single-Source Sheet Metal Manufacturing Partner

At FTI Manufacturing, we simplify your journey by being your one-stop partner. One vendor, one purchase order, and one accountable team driving your project to success.

One Destination

End-to-end Services, Unmatched Capabilities

FTI Manufacturing brings the full spectrum of precision sheet metal fabrication services under one roof. From rapid prototyping to full-scale production, our integrated process ensures faster lead times, seamless coordination, and exceptional quality.

One Vision

Redefining the Standard in Sheet Metal Fabrication

For decades, FTI Manufacturing has been shaping the future of precision sheet metal manufacturing. Our reputation is built on trust, innovation, and craftsmanship, backed by a team of engineers and experts dedicated to excellence. We don’t just deliver parts; we deliver confidence, consistency, and a vision of long-term partnership.

FTI Manufacturing Delivers Excellence

At FTI Manufacturing, we recognize that our clients create innovative products designed to endure extreme conditions, and serve highly specialized purposes. We take pride in getting it right the first time and delivering on schedule. We value our vital role in the success of your project and commit to doing our part to help you reach the finish line without delays.