Lightning Fast • Superior Craftsmanship • Engineering Expertise

Rapid Metal Prototyping

At FTI Manufacturing, we specialize in providing rapid sheet metal prototyping as a service, helping businesses quickly bring their ideas to life with precision-engineered parts and delivering quick turnarounds without compromising on quality. Our dedicated prototyping service is designed to deliver fast, accurate, and cost-effective solutions, ensuring every prototype meets the highest industry standards.

We don’t just focus on speed, we focus on precision, reliability, and consistency. From material procurement and engineering support to manufacturing and final delivery, our team is invested in every stage of the process. This commitment allows us to provide fast, dependable prototyping services that our clients can trust.

Whether you require simple sheet metal prototypes or complex assemblies, FTI Manufacturing offers the expertise, advanced equipment, and streamlined workflows to meet your requirements with some of the fastest production timelines in the industry.

Why Choose FTI Manufacturing for Rapid Sheet Metal Prototyping

Rapid Turnarounds: Receive instant quotes and get your prototypes delivered within days.

Superior Quality: We uphold strict quality standards to deliver precision and durability in every prototype.

Process-Driven Expertise: our team offers hands-on guidance and technical expertise, ensuring you get the best possible results.

Rapid Prototyping Process

At FTI Manufacturing, we believe a seamless rapid prototyping process is the foundation for faster innovation and efficient project execution. Our dedicated team of engineers, operation speciaists and business development managers work hand-in-hand to ensure your ideas move smoothly from concept to reality.

At every stage of our sheet metal rapid prototyping process, multiple skilled experts carefully validate, test, and ensure manufacturability of your design. This collaborative and detail-driven approach ensures that every prototype not only meets but exceeds the highest standards of precision and quality.

At FTI Manufacturing, we specialize in delivering custom sheet metal prototypes that are accurate, reliable, and production-ready. With our streamlined process, you can move from design to functional prototype in days, not weeks, keeping you ahead of deadlines and the competition.

Below is a detailed breakdown of our rapid prototyping workflow for your custom sheet metal parts!

How It Works

Sheet Metal Prototyping Rapid Quote Process

Designed to spec and on your desk in days, not weeks.

Step 1: Submit a Quote Request

With our advanced quoting tools and experienced estimators, you’ll receive highly accurate quotes within 24 hours. This ensures you can move forward with your project without delays.

Step 2: Upload Your Drawings

We support multiple file formats, including .step, .pdf, and more. Our engineering team carefully reviews each design, addresses potential challenges, and recommends the best solutions to ensure manufacturability and smooth production.

Step 3: Receive Your Prototype

Once fabrication and finishing are complete, your custom sheet metal prototype is delivered in just a few days. We ensure reliable and safe delivery through our trusted logistics partners or your preferred shipping method.

Step 4: Accelerate Your Time to Market

With fast turnaround times, precision engineering, and superior-quality prototypes, FTI Manufacturing helps you shorten development cycles and stay ahead of the competition. Our goal is to get your product market-ready, faster, smarter, and stronger.

In our rapid prototyping process, we combine speed, precision, and craftsmanship in every prototype, so your product is not only delivered quickly but built to perform.

Materials Options

We offer a wide range of materials for your rapid sheet metal prototypes to suit your needs.

Before we fabricate, bend, punch, or cut any sheet metal part, we always begin with the same critical question: What material is this part made of?

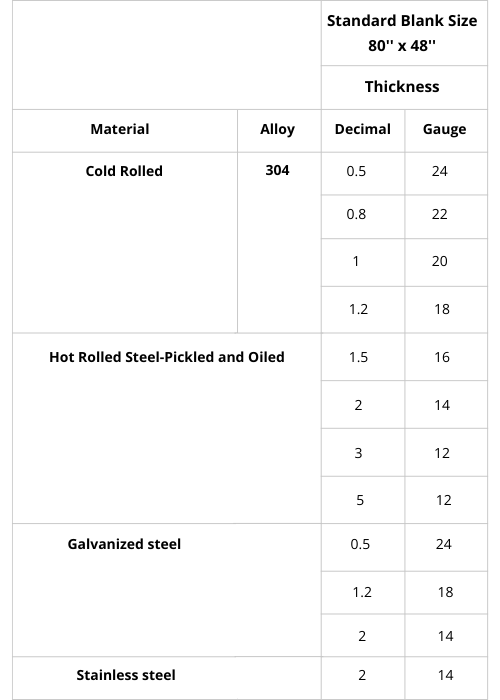

At FTI Manufacturing, we understand that choosing the right material is key to ensuring performance, precision, and durability. That’s why we stock a wide selection of sheet metal materials in various thicknesses, ready to support everything from rapid prototypes to large-scale production runs. Our materials list below shows our sheet metal material selection for prototypes that we usually carry. If you don’t see your required material listed, don’t worry. Special material sourcing is something we do regularly for our customers. Simply reach out, and we’ll find the right fit for your project.

Our in-house material selection includes:

Cold Rolled Steel (CRCA)

We frequently work with Cold Rolled Close Annealed (CRCA) steel for projects that demand strength, precision, and a clean finish. CRCA is known for its smooth surface, excellent formability, and dimensional accuracy. It doesn’t shrink during forming, making it ideal for components that require tight tolerances and sharp aesthetics.

Hot Rolled Steel – Pickled and Oiled (HRPO)

Hot Rolled Pickled and Oiled (HRPO) steel is a cost-effective choice for parts that require excellent workability and minimal internal stress. While it may have a more textured surface compared to CRCA, it’s a preferred option for robust structural parts and large fabrications.

Galvanized Steel (GI)

Galvanized Iron (GI) sheets come with a protective zinc coating that boosts corrosion resistance and extends product life, especially in challenging environments. GI is used for parts that are exposed to weather, moisture, or corrosive applications, helping you achieve both durability and performance.