S h e e t M e t a l F a b r i c a t i o n

Spot Welding

High-quality, cost-effective spot welding of sheet metal is performed in-house.

High-Quality • Precision Craftsmanship

In-House Spot Welding Sheet Metal

At FTI Manufacturing, our spot welding team brings precision, efficiency, and expertise to every project. While spot welding is often viewed as a straightforward method, our skilled operators ensure strong, consistent welds that meet both structural and aesthetic requirements. Using three stationary spot welding machines with 40 kAmp capacity, we can weld materials up to 6 mm thick, whether for prototypes or high-volume production.

Spot welding, also known as resistance spot welding, is a fundamental process in precision sheet metal fabrication. It joins metal surfaces without the need for screws or rivets by generating heat through electrical resistance.

High-strength copper alloy electrodes concentrate the current into a small “spot,” creating a secure, localized weld. FTI Manufacturing’s in-house spot welding capabilities deliver reliable, repeatable, and cost-efficient results for a wide range of industrial applications.

Spot Welding Sheet Metal Features

Spot Welding Benefits

Spot welding sheet metal with FTI Manufacturingallows our customers to:

- Join different materials with minimal distortion or warping

- Easily handle challenging welds on thin sheet metal

- Save time and reduce overall production costs

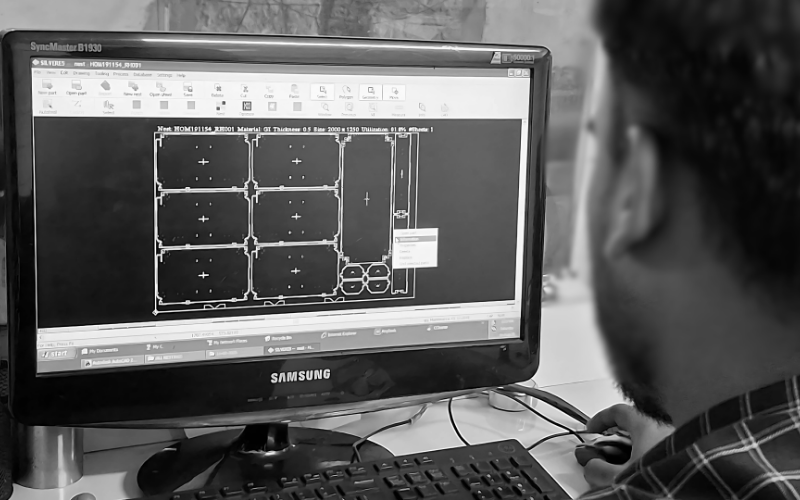

Engineering & Design Support

At FTI Manufacturing, our in-house engineering and design team provides end-to-end support from concept to production. Whether it’s new product development, design optimization, or reverse engineering, we work collaboratively with our clients to develop cost-effective, manufacturable solutions tailored to their specific needs.

Our team is proficient in handling a wide range of industry demands and production challenges. We assist in refining part geometries, simplifying fabrication processes, and reducing material and operational costs, helping our clients improve functionality without compromising efficiency or quality.

FTI Manufacturing supports direct import and unfolding of 3D models in formats such as .dwg, .step, .iges, .sldasm, .sldprt, and .dxf using tools like SolidWorks, AutoCAD, and other major CAD platforms. These files are seamlessly integrated into our CAM workflow, enabling faster processing, reduced errors, and shortened lead times for your sheet metal components

JIT / KANBAN for Smarter Manufacturing

At FTI Manufacturing, we leverage the Just-In-Time (JIT) inventory strategy to align production precisely with your ordering needs. This reduces idle inventory, optimizes costs, and ensures you receive a high-quality product delivered on time, every time, at a competitive price.

We pair JIT with the Kanban system to streamline our lean production practices. By setting clear minimum and maximum stock levels, we maintain a highly responsive pull-based system that adapts to your demand without unnecessary waste.

Our approach not only reduces excess inventory for both customers and suppliers but also ensures seamless production flow and faster lead times. With full pipeline visibility through our tracking systems, FTI Manufacturing keeps your supply chain running smoothly, reliably, and efficiently.

Why us?

- Are FTI Manufacturing’s Metal Spot welding Services Right for Your Next Project?

- Do you need spot welding processes that meet strict, project-specific requirements?

- Have other manufacturers turned away your blueprints, saying your designs are “too complex” or difficult to execute?

- Are you looking for a straightforward job but frustrated with long lead times?

At FTI Manufacturing, we simplify the entire precision sheet metal manufacturing process by offering in-house spot welding services as part of our full-service capabilities. By keeping these critical processes under one roof, we not only speed up project timelines but also eliminate the risks of relying on external supply chains. With complete oversight and control from prototyping to final shipment, FTI Manufacturing ensures every project is delivered with uncompromised quality, consistency, and on-time performance.

Our Promise

Spot Welding Guarantee

FTI Manufacturing is more than just a sheet metal fabricator, we are a manufacturing partner invested in your success. With over 35+ years of experience, we have built lasting client relationships by delivering not only high-quality parts but also the reliability, consistency, and trust businesses count on.

Comprehensive Capabilities Under One Roof

With a wide range of precision sheet metal fabrication services, including rapid prototyping, CNC machining, sheet metal forming, fabrication, and finishing, FTI Manufacturing provides complete solutions without the need for multiple vendors. This integrated approach ensures better quality control, faster turnaround times, and cost efficiency.

Invested in Your Process, Committed to Your Success

At FTI Manufacturing , we understand that choosing a manufacturing partner is about more than just capabilities, it’s about trust, collaboration, and results. We work closely with our customers at every stage, offering engineering expertise, process optimization, and reliable delivery that helps your projects succeed.

One Team

Your Single-Source Sheet Metal Manufacturing Partner

At FTI Manufacturing, we simplify your journey by being your one-stop partner. One vendor, one purchase order, and one accountable team driving your project to success.

One Destination

End-to-end Services, Unmatched Capabilities

FTI Manufacturing brings the full spectrum of precision sheet metal fabrication services under one roof. From rapid prototyping to full-scale production, our integrated process ensures faster lead times, seamless coordination, and exceptional quality.

One Vision

Redefining the Standard in Sheet Metal Fabrication

For decades, FTI Manufacturing has been shaping the future of precision sheet metal manufacturing. Our reputation is built on trust, innovation, and craftsmanship, backed by a team of engineers and experts dedicated to excellence. We don’t just deliver parts; we deliver confidence, consistency, and a vision of long-term partnership.

FTI Manufacturing India Delivers Excellence

At FTI Manufacturing, we recognize that our clients create innovative products designed to endure extreme conditions, and serve highly specialized purposes. We take pride in getting it right the first time and delivering on schedule. We value our vital role in the success of your project and commit to doing our part to help you reach the finish line without delays.